We're Not Just a "Mopar Shop" Anymore

If you've heard of California Calipers, there's a good chance it's because someone with a Charger, Challenger, or 300 told you about us. And honestly? That reputation was earned. We've powder coated thousands of Mopar brake calipers, dialed in those factory color matches, and helped countless Dodge owners get the look they want.

But here's what a lot of people don't know: we're not just a Mopar shop. We're certified automotive technicians with ASE credentials in brakes and suspension. That means we've been taking apart, rebuilding, and understanding brake systems on everything from German sports cars to American muscle to Japanese imports for years: long before we ever started powder coating them.

So if you're rolling in a Porsche, Camaro, Mustang, or pretty much any other performance car, this one's for you.

What Does "ASE-Certified" Actually Mean?

Let's be real: anyone with a powder coating gun and a YouTube tutorial can slap some color on a brake caliper. But that doesn't mean they should.

ASE stands for Automotive Service Excellence, and it's the gold standard certification for automotive technicians in North America. To earn an ASE certification in brakes, you need to pass a rigorous exam that covers everything from hydraulic theory to rotor runout to caliper piston operation. It's not just about knowing what parts are: it's about understanding how they work together to stop a 4,000-pound vehicle traveling at highway speeds.

Our ASE certifications in brakes and suspension mean we've proven we understand the mechanical systems we're working on. When we disassemble a caliper for powder coating, we know exactly what we're looking at. We can spot worn seals, damaged pistons, and potential failure points before they become problems. We know which parts need to be masked, which surfaces need to remain untouched for proper function, and how everything needs to go back together.

That's the difference between a "painter" and a technician who also powder coats.

Why Mechanical Knowledge Matters for Powder Coating

Here's something most people don't think about: powder coating isn't just an aesthetic process. It's a thermal process that involves heating components to 400°F for 15-20 minutes. That heat cycles through every part of the caliper, affecting seals, pistons, and internal tolerances.

If you don't know how a brake caliper actually functions, you might powder coat over surfaces that need to remain bare for proper sealing. You might fail to properly clean internal passages where brake fluid flows. You might reassemble components in the wrong order or torque bolts to incorrect specifications.

With our background in brake repair and rebuilding, we know:

- Which caliper components can handle powder coating temperatures and which need to be removed

- How to properly disassemble multi-piston calipers without damaging internal seals

- What tolerance specifications need to be maintained for proper operation

- How to identify calipers that need rebuilding before they get powder coated

- The correct reassembly procedures for different caliper designs

This isn't just about making your calipers look good. It's about making sure they continue to function safely after we're done with them.

Beyond Dodge: The Performance Cars We Work On

While we built our reputation on Mopar products, our mechanical expertise extends across the entire automotive spectrum. We've successfully powder coated and restored brake calipers for:

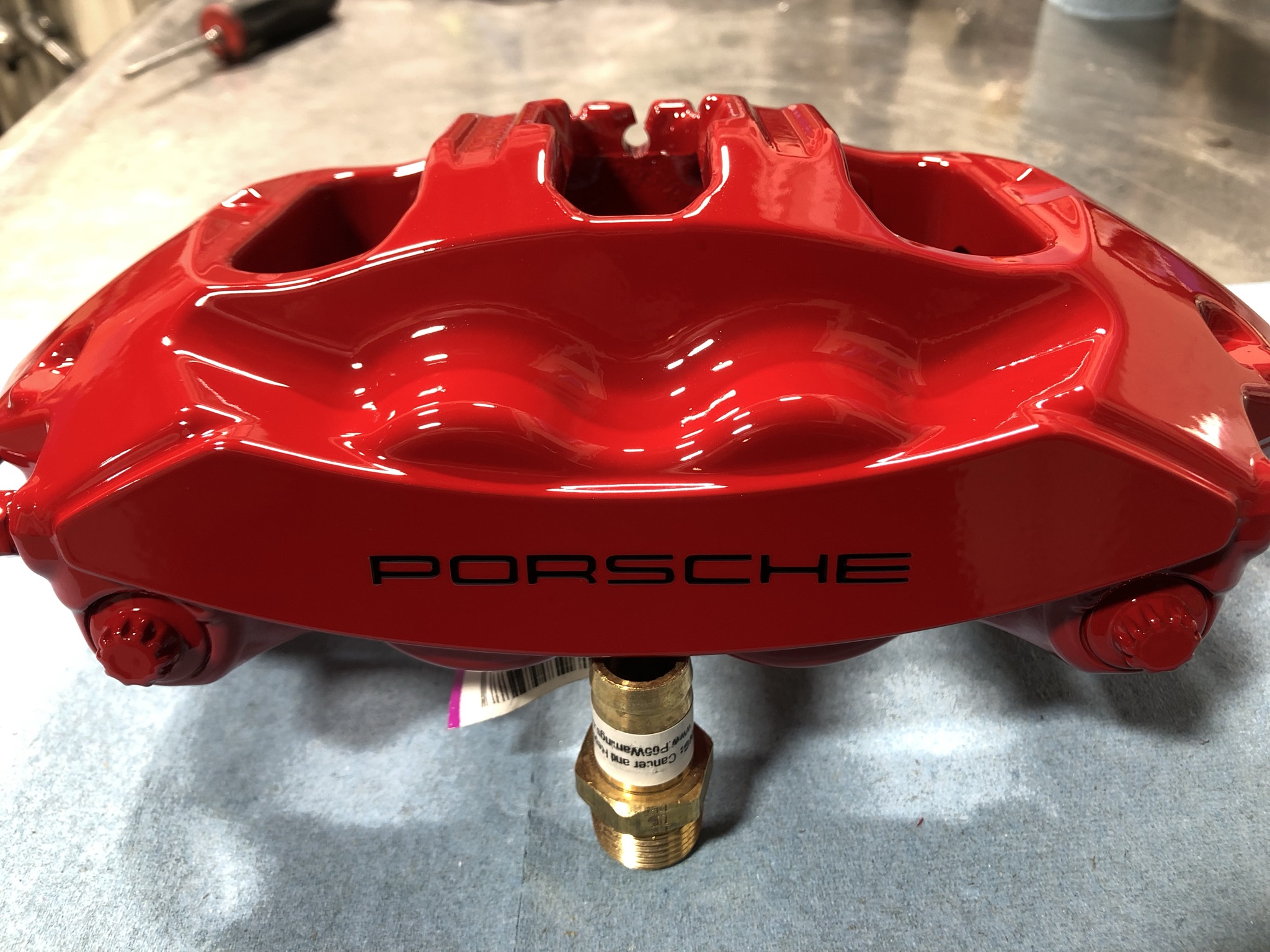

Porsche Owners: Whether you're running factory calipers on a 911 or Boxster, or you've upgraded to a big brake kit, we understand the precision engineering that goes into German braking systems. Porsche calipers often feature aluminum construction and complex internal passages that require careful handling during the powder coating process.

Camaro Enthusiasts: From base models to ZL1s, we've worked on the full spectrum of Camaro brake systems. Modern Camaros often come with Brembo calipers from the factory, and we know exactly how to handle these high-performance components. Whether you want to match your calipers to your exterior color or create contrast with your wheel finish, we've got you covered.

Mustang Fans: GT350s, Mach 1s, standard GTs: we've powder coated calipers for every generation of Mustang. Ford's Performance Pack brakes require the same careful attention to detail as any high-end system, and we treat them that way.

Import Performance Cars: Honda, Toyota, Nissan, Subaru: if it has brakes, it can be customized. Import car owners often have unique color requests and specific aesthetic goals, and the powder coating process delivers the durability these enthusiasts demand.

The Technical Side: What We Do Differently

When you send us your calipers, here's what happens behind the scenes:

Initial Inspection: We start by examining every caliper for mechanical issues. Seized pistons? Damaged bleeder screws? Corroded mounting brackets? We identify these problems before powder coating begins. This is where our ASE training really shows its value: we're not just looking at the outside of the part.

Proper Disassembly: We remove all seals, pistons, and hardware that shouldn't go through the powder coating process. This isn't about taking shortcuts; it's about preserving the integrity of your brake system.

Surface Preparation: Calipers are chemically stripped, sandblasted, and cleaned to bare metal. This removes all old paint, brake fluid residue, rust, and contaminants. It's a more thorough process than most "quick" powder coating shops use.

Masking and Protection: Critical surfaces like caliper bores, mounting faces, and bleeder screw threads are carefully masked. These areas need to remain uncoated for proper function and fit.

Powder Application and Curing: The powder is electrostatically applied in our controlled environment, then cured at the proper temperature for the proper duration. We're not rushing the process: we're doing it right.

Quality Control: After curing, we inspect every surface. Then, if you've requested decals or logos, we apply them and add a clear coat layer for protection and depth.

Reassembly Preparation: We provide your calipers ready for new seals and hardware installation, or we can handle the complete rebuild if you prefer.

A Color for Every Performance Machine

Color Options for Every Style

One of the best parts about working with California Calipers? You're not limited to "Mopar colors" anymore. While we still offer those factory-matched Plum Crazy Purples and Go Mango oranges, we can also provide:

- Classic Porsche colors like Guards Red or Speed Yellow

- Mustang-inspired hues like Grabber Blue or Race Red

- Custom color matching to your vehicle's specific paint code

- Metallic, gloss, or matte finishes depending on your preference

- Multi-tone or two-color combinations for a unique look

Check out our full color selection to see what's possible.

Why Performance Car Owners Choose Us

The automotive customization world is full of shops that can make things look good. What separates California Calipers is our foundation in actual automotive repair and maintenance. We're not artists who learned to work on cars: we're technicians who learned to make them beautiful.

For Porsche, Camaro, Mustang, and import owners, this distinction matters. You're not driving a grocery-getter; you're driving a performance machine that demands precision. Your brakes are a critical safety system, not just a styling opportunity. You need someone who respects both aspects of the project.

Our ASE certifications mean we understand the engineering behind your vehicle's braking system. Our powder coating expertise means we can deliver a finish that looks factory-fresh and lasts for years. And our extensive experience across multiple brands means we've probably worked on something very similar to your specific vehicle before.

Getting Started with Your Project

If you've been thinking about customizing your brake calipers but weren't sure where to start, here's the good news: we make the process simple. Whether you're local to the California Central Coast or shipping from across the country, we've streamlined the entire experience.

Visit our shop page to see our current product offerings and get pricing. Want to see examples of our work across different vehicle types? Check out our photo gallery to see everything from subtle refinishes to bold custom colors.

And if you're not sure whether powder coating is right for your specific application, just reach out. We're happy to discuss your project, answer technical questions, and provide honest recommendations based on our years of brake system experience.

The Bottom Line

California Calipers started as a Mopar-focused operation, and we're proud of that heritage. But our capabilities: and our customer base: have grown far beyond a single brand. Our ASE certifications in brakes and suspension aren't just letters on a wall; they're proof that we understand the mechanical systems we're customizing.

Whether you're building a show-winning Porsche, tracking your Camaro, daily-driving your Mustang, or modifying your import project car, you deserve brake caliper powder coating from professionals who know what they're doing. Not just in the paint booth, but under the hood where it really counts.

About California Calipers / Contact Us

California Calipers

831-435-9558

californiacalipers@nullgmail.com

https://www.californiacalipers.com/

Recent Comments